Thermal Simulation & Climate Control Concepts

PRACTICAL, EFFICIENT & INNOVATIVE

We develop, optimize, and verify climate control concepts for our clients.

Where technical systems and power electronics are supposed to reliably perform, an optimal cooling in consideration of radiation, thermal conduction, and convection is essential. Using 3D simulation software, we are able to analyze the cooling demands of products and systems and provide quick results. With the aid of CFD (Computational Fluid Dynamics Simulation), virtual prototypes can be analyzed for their operational reliability, typical properties, and their future performance. Thus, life spans of electronic components and entire technical systems can be extended without a high use of energy and attached maintenance costs. Our intelligent, custom-designed climate concepts, increase the utility of your systems and save precious time and money.

Therefore, the benefits of numerical simulation are obvious:

- Climate and location simulations without real material usage

- Optimization of prototypes by determining critical points

- Easy improvement through simultaneous change of components

- Easy verification of existing products

- Quick results from CAD data

- Cost and time savings on development, tools, prototyping, material usage, measurements etc.

- Quick commercial market presence of new products

CLIMATE CONTROL OF ENCLOSURES

With 3D simulation systems, we provide quick results on climate control and ensuring functionality of system integrations.

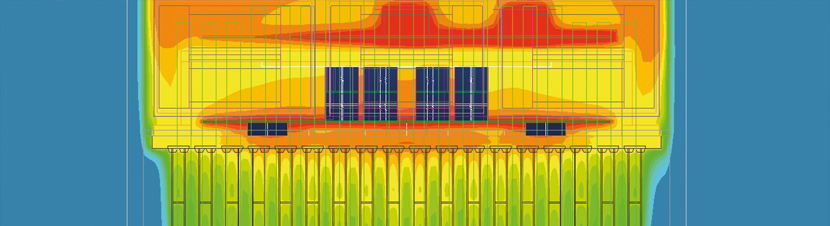

ELECTRONICS COOLING

The requirements on thermal management are growing due to higher power loss. In the fields of electronics cooling, the CDF analysis applies to almost every aspect of designing components, boards, boxes, cabinets and fans.

FAN MANAGEMENT

With numerically correct settings of the actual operating point, operating states, efficiency,

and flow fields can be calculated by their characteristic lines. This provides an accurate choice of fans and facilitates system adjustment and optimization.

HEAT SINK CALCULATION & DESIGN

Heat sink mapping via CFD allows monitoring of relevant conditions and influencing factors simultaneously, realistically, and in consideration of their relationships. Based on this, we are able to give quick and precise statements of the thermal performance.